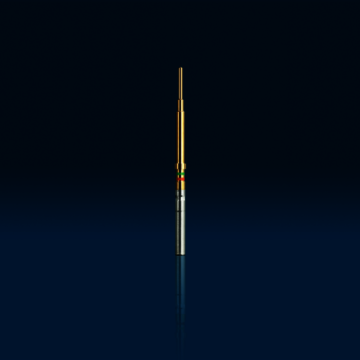

Medical Equipment

By Your Side With Safer, Smaller and innovative Contacts

Due to our long-standing experience in the machining of high-precision contacts, and mindful of the challenges related to the Medical sector, we have been manufacturing electrical contacts co-designed and produced specifically for medical connectors and applications. Along with traceability feature, their technology facilitates :

- Surgical time reduction

- Less invasive procedures

- Remote care

- Patients' prompter recovery

- Costs optimization for patients and professionals

Our engineers are involved from the very first stage of your project. They will assist you in the design of the electrical parts to ensure its optimal production for highest performance. They will also provide you with technical support throughout the project.

In order to meet your demand, our expert technicians will then manufacture a prototype which will be subjected to numerous quality control procedures which can be customizable to your specs and all prototypes will be submit to your validation before mass production.

Our medical electrical contacts are easy to assemble on your different connectors.

A glimpse in some connectors we can be assembled onto:

- Embedded electronics connectors

- PCB

- Push-pull circular connectors

- Push-pull connectors

- RF connectors

- Cable

- Disposable plastic connectors

- Hybrid circular connectors

- Receptacle systems

- Power cords with retention systems

- Lighted hospital-grade cords

- magnetic medical connectors, etc.

A glimpse in some medical applications:

- Patients monitoring devices/ systems

- Surgical robots

- Imaging scopes

- Probes

- Pace makers

- Cardiac MRI equipment

- Pumps

- Defibrillators

- Diagnostic and digital imaging equipment

- Therapeutic and implantable devices

- Medical imaging (MRI Machines, CAT scanners…)

- Electrophysiology catheters…etc.

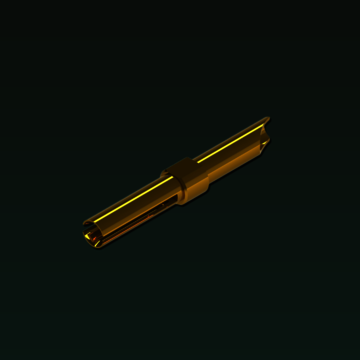

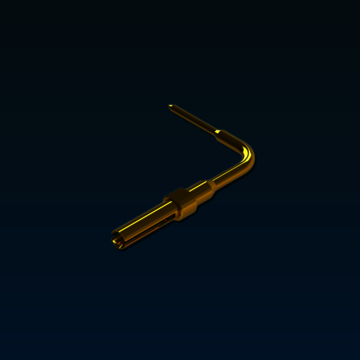

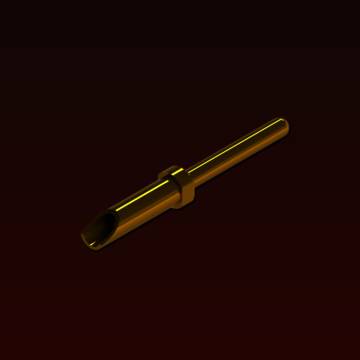

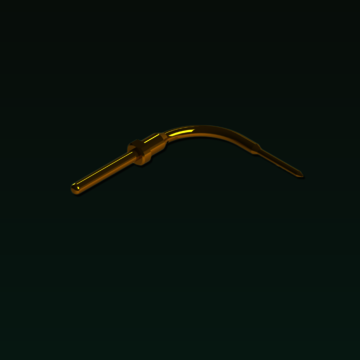

Thanks to our machines with high technological capacities and capabilities and to our vertical integrated production line, we can manufacture standard mono bloc and custom-made, inners bodies, pin and socket contacts of different sizes, including nano contacts.

Our certifications

Certifications

EN 9100

REACH Compliant

RoHS Compliant

Product Overview