Setup

High capacity and precision production processes

Our contact manufacturing operations are split across several workshops, each with their own expertise, but working together to optimize costs and lead times:

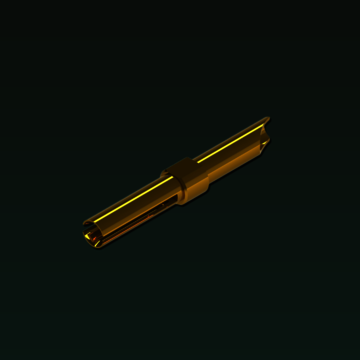

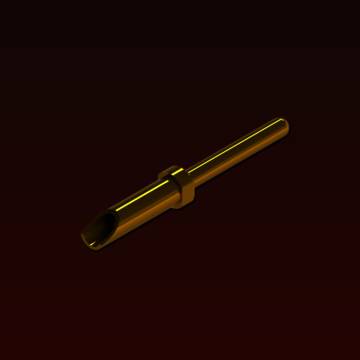

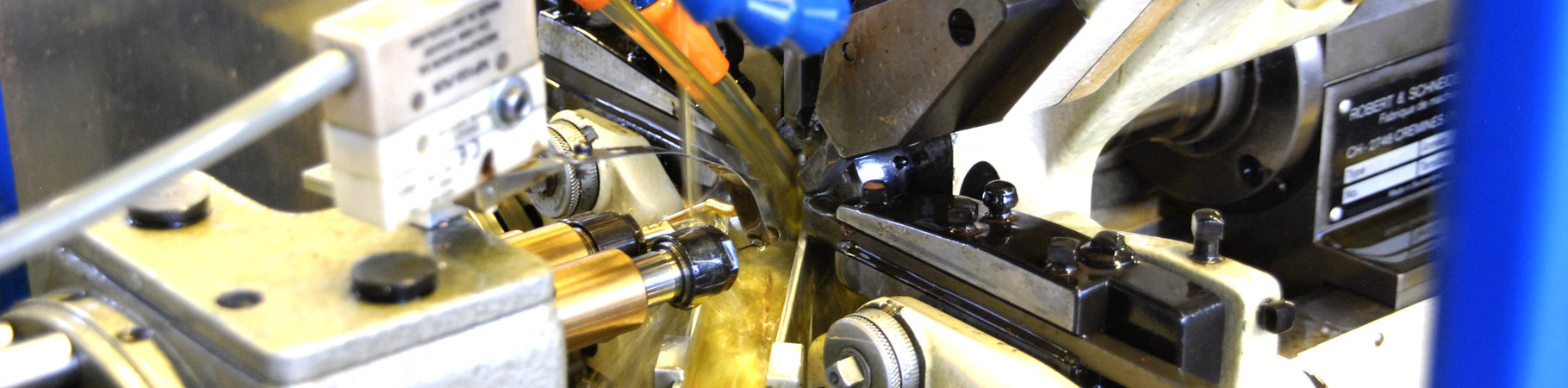

- Screw machining: with automatic swiss cames, as well as cam-driven and digitally-controlled machines such as CNC routers, milling machines, which allows us to maintain a high production rate and to produce complex shapes.

- Secondary-operation machining (Transfer): through which we can apply our expertise in performing complex operations: in particular when working with complex shapes.

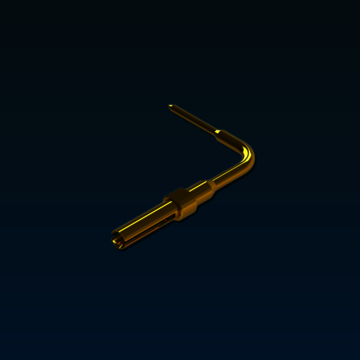

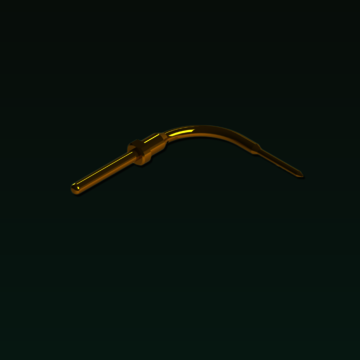

- Bending: another area of our expertise, producing simple and complex bent contacts, including bendings in multiple locations, such as the "S-shaped contact". All of these procedures are performed manually or automatically depending on the volume.

- Partial annealing: We have developed a partial annealing process to improve our customization capabilities, working on small-diameter as well as long and fine parts, using flame annealing and induction annealing machines specifically designed for this operation.

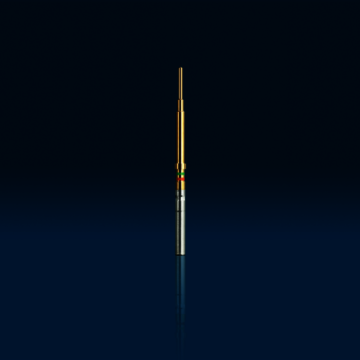

- Plating: We are specialized in galvanoplasty, nickel plating, copper plating, SWISSCOAT, silver, gold, selective gold, and more.

- Assembly: during which we perform assembly of hood and crimping operations, with 100% testing of contact retention forces.

- Colour-coding: allowing us to provide as per standard specs or customize your contacts using coloured bands or dots.

- Mechanics & Tooling: through which we oversee the production of our own cams, tooling, etc., allowing us to control costs, lead times, and quality.

- Washing: a crucial operation to clean all parts before any further work or shipping.

- Heat treatments: to increase the hardness or to reduce on the electrical contacts, also to homogenous the material.

- Sand blasting: finalising the cleaning of parts for smooth burr-free products.

Our certifications

Certifications

EN 9100

REACH Compliant

RoHS Compliant

Product Overview